Superior protection, durability, and aesthetic appeal

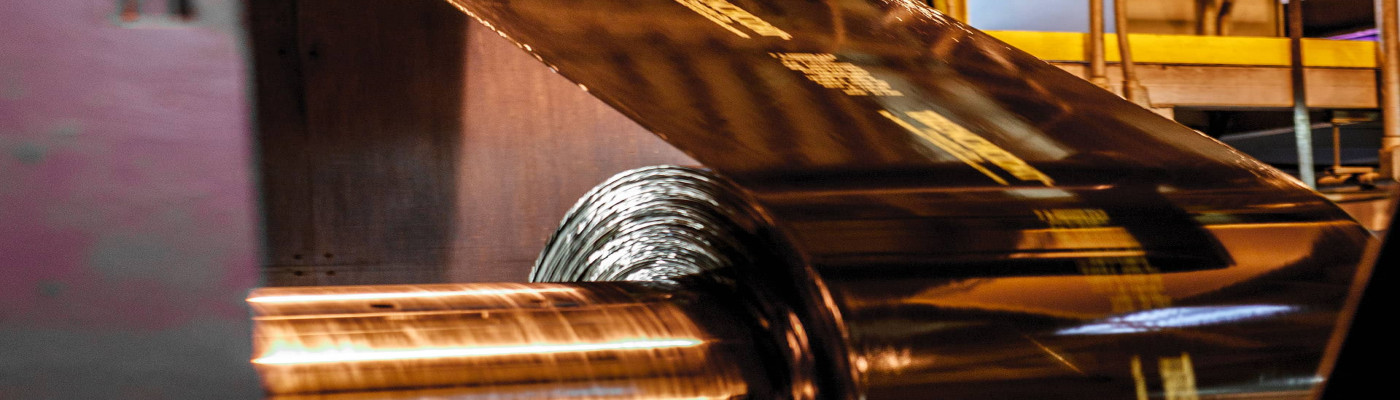

Laminating improves the metal’s resistance to abrasion, UV rays, chemicals, and weathering, enhancing its durability and longevity. It also enhances the metal’s appearance by adding texture, gloss, or other desired visual effects. Laminating ensures that metal surfaces maintain their integrity and appearance, making them suitable for various applications, even in challenging environments.

Related Featured Story

Related Case Study

Explore Related Laminating

Cleaning & Pretreating

Achieve optimal results for superior end productsHADID Precoat Metals guarantees premium quality, durability, and performance for coated products with our thorough cleaning and pretreatment expertise. We eliminate dirt, debris, oils, and contaminants from the metal surface, establishing a smooth and uniform substrate that ensures a superior bond between the metal and coating. Our precise pretreatment, utilizing specialized chemicals, optimizes the surface for enhanced paint adhesion and corrosio...

Explore

Cut-to-Length

Meeting the precise needs of customersCoil coating cut-to-length is the process of cutting metal coils into specific lengths according to customer requirements. This efficient and accurate customization of metal sheets eliminates the need for customers to cut the coil themselves. This capability ensures that our customers receive their orders tailored to their exact needs, saving time and resources in the production process.

Explore

Embossing

Discover added dimension through skilled embossing techniquesEmbossing is a specialized technique in the coil coating process to create raised or textured patterns on metal surfaces. The result is a visually appealing, textured surface that adds depth and character. This technique enhances the overall appearance, making it more attractive and suitable for various uses.

Explore

Printing

Cutting-edge printing processes redefine industry standardsHADID Precoat Metals offers innovative coating solutions that involve printing designs or patterns on metal coils before they undergo further fabrication. Our expertise in coatings allows for efficient and precise applications on metal surfaces, enhancing the appearance and aesthetics of the final products.

Explore

Fabrication

Hadid Galvanizing doesn’t just protect steel—we help build it right from the beginning. Our metal fabrication services are designed to deliver precision, durability, and performance for every type of steel structure, from industrial platforms to custom steel components. Hadid Offers: Custom Fabrication Solutions We cut, bend, drill, and assemble steel components based on your exact specifications—whether for construction, telecom, energy, or infrastructure. Welding &am...

Explore

Slitting

Enhance efficiency, minimize waste, and maximize materialA critical capability in the coil coating industry, slitting is cutting wide metal coils into narrower strips or coils of specific widths. Slitting allows for efficient handling and distribution of the coated metal, accommodating various industry needs. Customizing the width according to customer requirements or applications minimizes waste and optimizes material usage, saving time and resources in the production process.

Explore