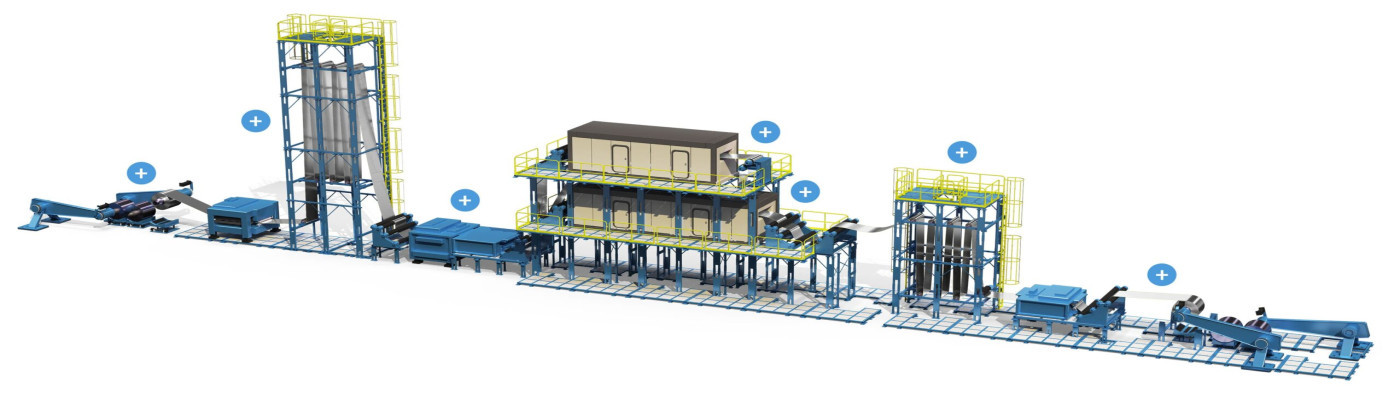

The coil coating process applies coatings and laminates to metal coils in a continuous, automated manner before fabrication. With metal coils up to 72 inches wide and traveling at 700 feet per minute, both sides are cleaned, treated, primed, top-coated, and cured before recoiling for shipment.

Coil coating is known for cost-effectiveness, aesthetics, field performance, and sustainability. It operates as a closed loop system with over 98% VOC capture and conversion to fuel. In the European market, the finished product is referred to as prepainted or precoated metals or coils.

Related Featured Story

Related Case Study

Explore Related Coil Coating Process

Coating Solutions

HADID Precoat Metals has been at the forefront of cutting-edge metal coating and treatment systems for over six decades, turning product wish lists into reality and pioneering emergent coatings. With an in-depth understanding of each supplier’s capabilities, we optimize your coating choices, providing you with the best solutions available in the market. And when the perfect feature doesn’t exist, our dedicated Innovation Team is ready to craft something entirely new.Strategic collaboration w...

Explore